How I Design

Every project is unique, every solution is different. Design is rarely linear, therefore my approach is agile and thoughtful. I strategically draw from an ever-expanding ‘tool kit’ with an adaptable formula to efficiently deliver the best result for each client.

Below are some of the skills in my arsenal to get the job done.

Sketching

Whether it’s on a napkin while we chat or a focused ideation session, hand sketching is often the first and fastest way to get ideas on paper. Simple, yet highly effective form of visual communication.

Rendering

Comfortable with either hand or digital rendering, this is how I begin to flesh out a concept. It keeps the design focused on the big picture, while helping align stakeholders with the vision. This is high-level design.

Scale Modeling

I often do my best thinking with my hands, and not everyone can understand drawings. I utilize models to conceptualize complex spaces and objects. They are a powerful tool, benefitting both designer and client.

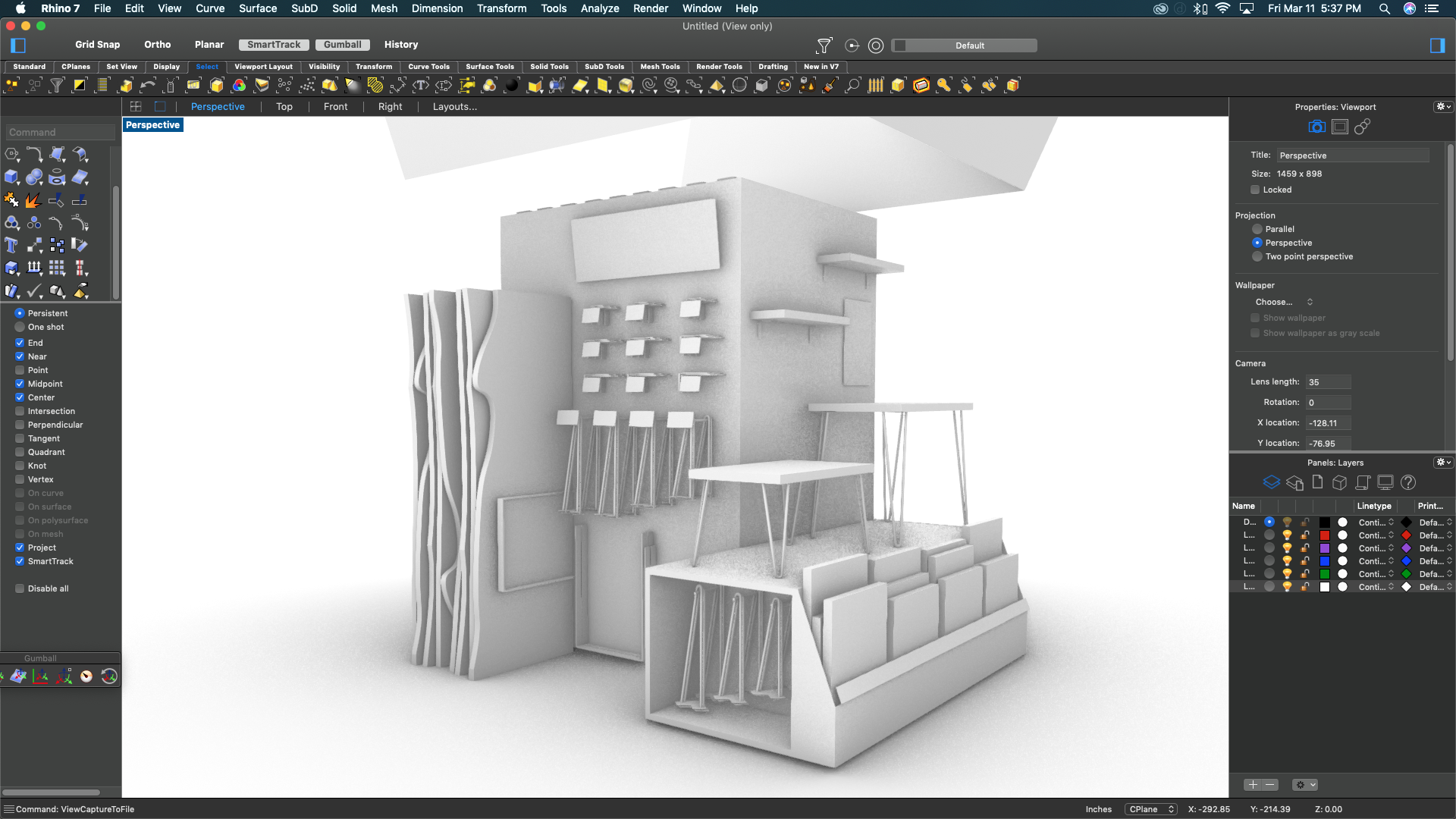

CAD

Rhino, Fusion360, solidworks, etc. CAD is where the details take shape. This is rarely where I like to start a design. Instead, it is where I figure out how to make it. Practical refinements, hardware selection, manufacturing files and shop drawings originate here.

3D Printing

Whether I’m creating functional parts or simply testing out a concept, 3D printers have been a part of my workflow for over a decade. I am adept at operating them as I am, building and troubleshooting them.

CNC

Bringing complex ideas to life often requires a working knowledge of complex machines. I create cut files and toolpaths for a variety of CNC machines.

Metal Fabrication

Welding, forming, cutting, machining, grinding… I have extensive, hands-on experience working with all sorts of metals and processes. I leverage this knowledge to make production-grade parts or simply design more efficiently.

Casting & Molding

I have created molds for composites, plastics, and metals. And have a working knowledge of rotomolding, injection molding, blow molding, and thermoforming.

Woodworking

Some of the first tools I ever used were woodworking tools, and I have been crafting with the material ever since. Everything from rough-in framing to cabinetry, to fine woodworking, I’ve tried it and loved it.

Machinery Operation

I am forklift certified and have operated a wide variety of heavy machinery from tractors and lifts to excavators and semitrucks. Sure, this means I’m a qualified operator for big jobs, but more importantly, I can effectively design and project manage with key insights into the needs of operators.

Production Graphics

I have produced and installed graphics on nearly every substrate and medium for projects around the world. This practical experience allows me to create bold exhibits with an eye for production from the start.

Aquarium Design

Keeping saltwater aquariums and reef tanks for the last 10 years has taught me much about plumbing, Life Support Systems, lighting design, water chemistry and more.

Aviary Design

I’ve been making aviaries from the time I was an enthusiastic middle schooler with a few game birds. I’ve designed, built and maintained meshed habitats of all sizes, from simple post and beam with hardware cloth to complex cable rigging with woven steel mesh.

Terrarium Design

I have created a wide range of terrariums, vivariums and paludariums from concept to installation. I excel at lighting design and hardscaping, and have key insights into substrate engineering, water features, bioactive designs, structural and automation.

Brand Strategy

I use standards guides, storytelling and a clear vision of a brands identity to craft experiences that connect with audiences on an emotional level and communicate with a unified voice. Every product I design supports and strengthens the tone of your brand.